Q: What is the difference between a tailor-made suit, ready-to-wear clothing and made-to-measure clothing?

Ready-to-wear clothing (base)

Ready-to-wear clothes, from the viewpoint of customer, work simply: You go to the shop, choose from the goods that are currently in stock and are available in “your” size, pay and leave with an item of clothing in your bag. The size of the standard ready-to-wear suit is given only by the width of the shoulders. Some producers even add a version with elongated sleeves. This is but the only size determining whether the suit fits you or not. It follows that if you have the same width of shoulders as a person 10 kilos lighter or heavier, you will wear the same suit. The same applies for two men with the same width of shoulders, but one with a height of 195 cm and the other with a height of 170 cm.

For an “ideal result” you still have to see the dressmaker to have the trouser-legs shortened, the jacket taken in or to modify the clothing in some other way.

Made-to-measure clothes

Made-to-measure is a basic way of non-serial suit making, when the customer is measured, he/she may choose the details within the given categories (buttons, hemming, …), and only on this base is the clothing made. The cut is not made from scratch, but only basic commercial cuts are modified. This way you will get a 95% result, but you will not able to compensate the real significant difference from the norm.

Bespoke tailoring

Bespoke tailoring

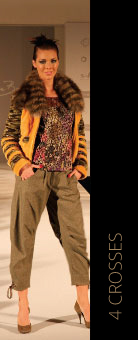

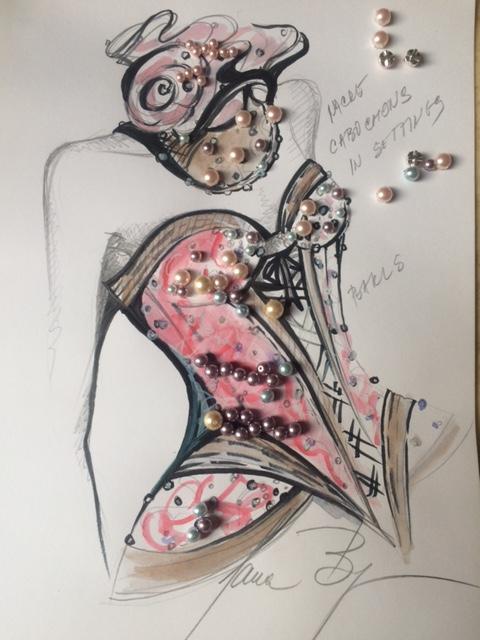

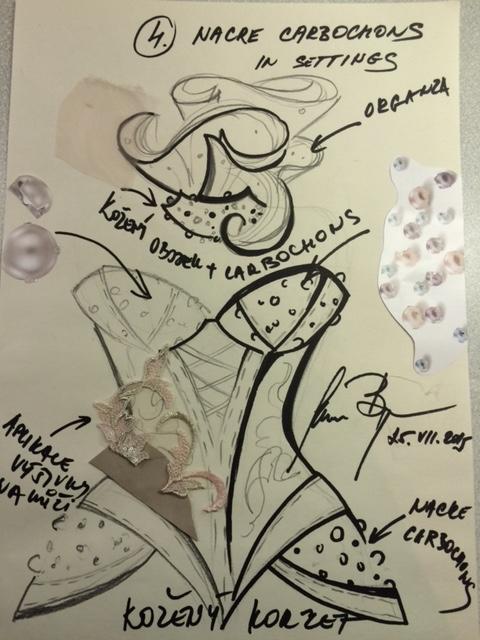

Bespoke tailoring is the real king of the tailor-craft. The customer can choose really anything from the fabric up to special pockets and the resulting piece of clothing arises utterly from scratch according exactly to his/her physiognomy. Based on your measurements, your own cut is designed.

On the suit, any element can be made. Not only in the cut or the design, you are not limited by absolutely anything.

Before you receive the finished suit, you will undergo at least two fittings. This is so that the suit will fit you in every detail.

During the manufacturing of the suit, almost no instruments are used except for the tailor’s hands. The only ones are a sewing machine, used for stitching of some parts, and the press for sticking of reinforcements due to lightness of today’s materials. Nothing more is needed for the manufacturing.

The manufacturing of the suit is done by a maximum of two persons, who bear the full responsibility for the result. The suit does not pass from hand to hand, as in ready-to-wear or made-to-measure manufacturing.

For a perfect result, it is necessary to go through two fittings with an experienced tailor. But thanks to this, the suit literally fits like a second skin.

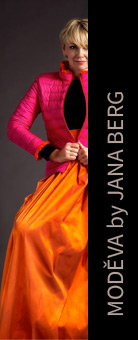

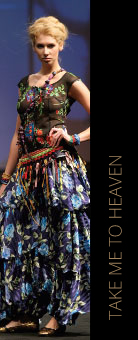

Q: How much will a model with the Jana Berg trademark cost?

The price consists of the price of work and material costs. The price corresponds with the high quality of fabrics and the perfect processing (haute couture). Models from our workshop are a long-term investment, because they are exceptional by their quality, workmanship and design. They are not susceptible to fashion trends, and they are not only clothing tailored to your figure, but mainly tailored to your soul. It is only up to you how much you are willing to invest in yourself and therefore how much money you will spend with us.

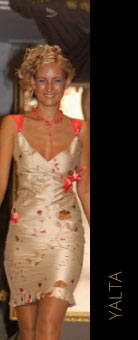

Q: How long does it take to make a model on order?

Due to the fact that we are employ all our tailors, we are able to set the pace of production and we can meet the marginal terms of the demand, but it must be taken into a consideration that every our product needs its production time so that the quality of processing would not be compromised. Our view is that if the commission from ordering to delivery takes more than 4-6 weeks, such service loses its appeal and signification for the client. And the client’s satisfaction is our top priority.

Q: How much will a model with the Jana Berg trademark cost?

The price consists of the price of work and material costs. The price corresponds with the high quality of fabrics and the perfect processing (haute couture). Models from our workshop are a long-term investment, because they are exceptional by their quality, workmanship and design. They are not susceptible to fashion trends, and they are not only clothing tailored to your figure, but mainly tailored to your soul. It is only up to you how much you are willing to invest in yourself and therefore how much money you will spend with us.

Q: How long does it take to make a model on order?

Due to the fact that we are employ all our tailors, we are able to set the pace of production and we can meet the marginal terms of the demand, but it must be taken into a consideration that every our product needs its production time so that the quality of processing would not be compromised. Our view is that if the commission from ordering to delivery takes more than 4-6 weeks, such service loses its appeal and signification for the client. And the client’s satisfaction is our top priority.